If your work involves handling chemicals, even something as common as cleaning agents or paints, chances are, you’ve come across labels with scary-looking symbols or detailed warning statements. But do you know what they mean? And more importantly, are you using them to keep your team safe?

That’s where the Globally Harmonized System, or GHS, comes in.

Designed by the United Nations, GHS makes chemical safety easier to understand across industries and countries. For workplaces in Singapore, whether you’re running a construction site, a manufacturing line, or a small cleaning business, understanding GHS isn’t just good practice. It’s the law, and it could save lives.

Let’s break it down in simple terms.

What Is the Globally Harmonized System (GHS)?

The Globally Harmonized System of Classification and Labelling of Chemicals is exactly what it sounds like: a way to standardize how we classify and communicate chemical hazards, no matter where you are in the world.

Before GHS, different countries had their own rules. What was considered “toxic” in one place might not have the same label somewhere else. That kind of confusion led to accidents and serious injuries, especially when chemicals crossed borders or workers changed jobs.

GHS solves that by creating a universal language for:

Classifying chemical hazards

Labelling containers clearly

Providing Safety Data Sheets (SDS) in a consistent format

In 2023, GHS is used in over 100 countries, including Singapore, and it’s an essential part of managing workplace safety.

Why GHS Matters for Your Workplace

Singapore has a strong reputation for high safety standards, and chemicals are no exception. Whether you’re working with solvents, adhesives, disinfectants, or acids, using the Globally Harmonized System helps you:

Stay compliant with the Workplace Safety and Health (WSH) Act

Communicate hazards clearly to all workers, regardless of background

Prevent accidents and protect lives

GHS isn’t just for chemical manufacturers or large corporations. If you store, use, or transport hazardous substances, it applies to you, even if you run a small cleaning crew or repair shop.

Who It Affects

Almost every industry will be affected by the GHS. You must adhere to the GHS requirements if your company belongs to one of the following industries:

- Chemical manufacturing

- Petrochemicals

- Electronics

- Metalworking

- Paint manufacturing

- Printing

- Transport equipment

- Storage and warehousing

For more information on the GHS and its requirements, please refer to the GHS booklet.

What Does GHS Include?

GHS may sound technical, but once broken down, it’s pretty straightforward. It’s built around three main components: how hazards are classified, how they are labeled, and how information is communicated.

Hazard Classification

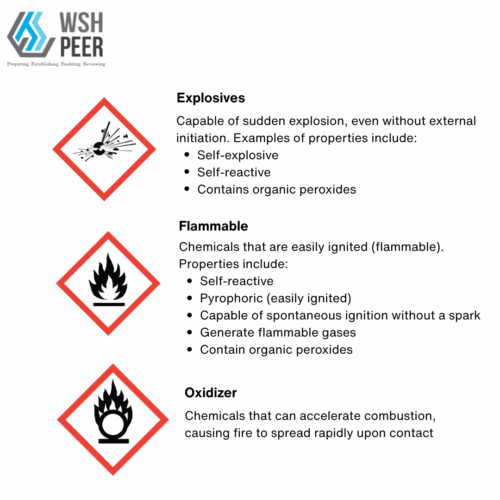

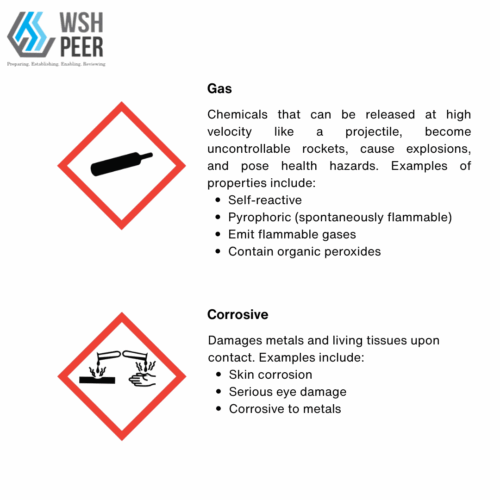

Physical Hazards

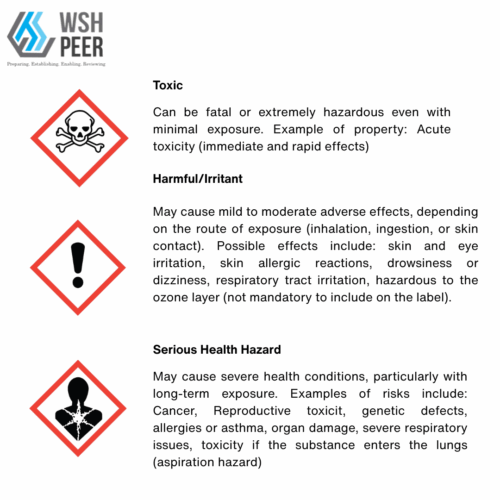

Health Hazards

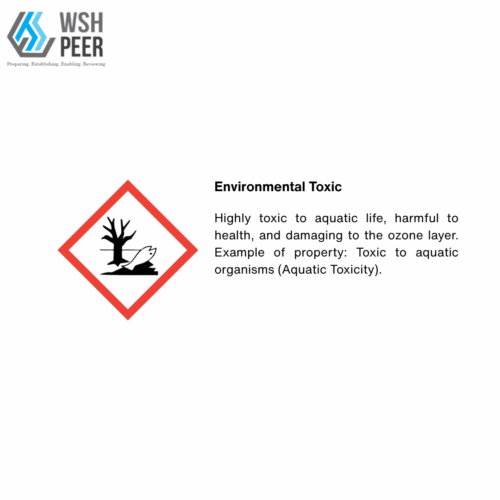

Environmental Hazards

Standard Labels

GHS labels are designed to be easy to recognize and understand. They include:

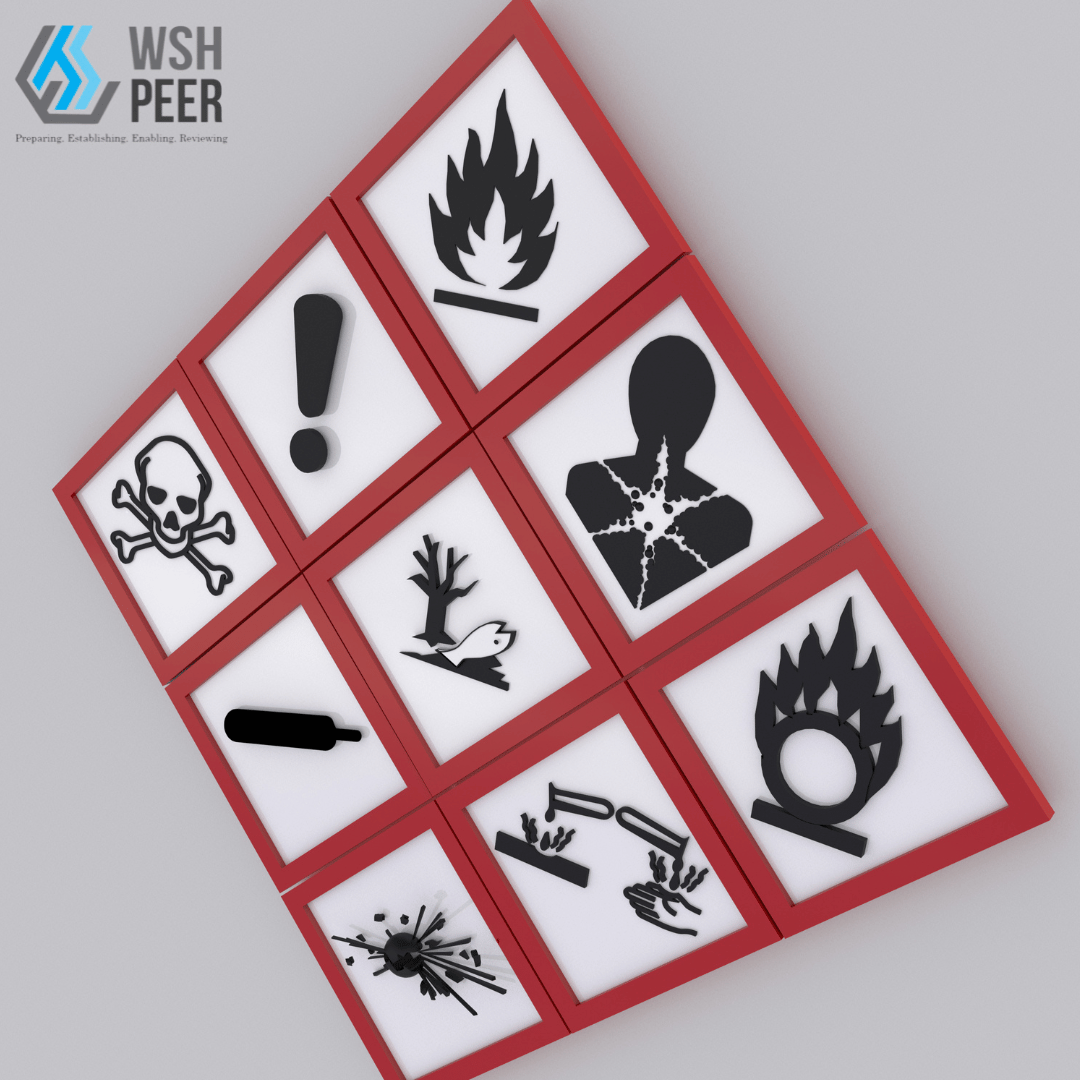

Pictograms: Those diamond-shaped symbols with bold graphics (like flames or skulls)

Signal Words: “Danger” or “Warning” to show how serious the hazard is

Hazard Statements: Simple descriptions like “Causes severe burns” or “Highly flammable”

Precautionary Statements: What to do to stay safe (e.g. “Wear protective gloves”)

Supplier Details: Who made or supplied the chemical

Label Information Items

The table below lists all the required label information items of a full GHS label.

Label Items | Example |

Product name | Isopropyl Alcohol |

Pictograms | |

Signal word | DANGER |

Hazard statements |

|

Precautionary statements |

|

Supplementary information | Empty uncleaned drums can still be dangerous, keep labelled until decontaminated, then remove or deface the label. For further information on this product, refer to Safety Data Sheet. |

Supplier information | United Nations Chemical Company Ltd. |

Safety Data Sheets (SDS)

This is the document that tells the full story behind a chemical. Every SDS has 16 sections, covering everything from first-aid instructions to safe storage and disposal.

In Singapore, all SDS must follow the GHS format. And they need to be readily available to employees, either in hard copy or digital format.

How Singapore Applies the Globally Harmonized System

Singapore started rolling out GHS guidelines more than a decade ago, and today, they’re part of everyday compliance.

Here’s what’s expected of employers:

Classify chemicals based on their hazards

Label all containers clearly using GHS rules

Keep SDS on-site for every chemical used

Train employees to understand labels and SDS

Maintain a chemical register, updated regularly

You can have the most accurate labels and updated SDS, but if your staff doesn’t know how to use that information, it won’t protect them.

That’s why worker training is essential. In fact, it’s a requirement in Singapore.

Key topics to cover in GHS training:

How to read and interpret GHS labels

What to do in case of spills, leaks, or exposure

How to choose and use PPE (personal protective equipment)

Where to find and how to use the SDS

Training should be part of your onboarding process and repeated regularly, especially when new chemicals are introduced.

Final Thought About Globally Harmonized System

The Globally Harmonized System isn’t about ticking boxes. It’s about giving everyone, from workers on the ground to business owners, a clear, consistent way to understand chemical hazards and stay safe.

In Singapore, with its high standards and emphasis on workplace safety, GHS plays a vital role. When done right, it builds a safer, more confident workforce, and reduces risks across the board.