Workplace safety is essential, especially in high-risk areas like construction sites, factories, and oil and gas facilities. One important tool used to keep workers safe in these environments is the permit to work (PTW) system. This system helps make sure that dangerous tasks are done in a safe and controlled way.

A permit to work is an official document that gives permission for a worker or team to carry out a specific task in a hazardous area. It clearly states what the job involves, what the risks are, and what safety steps must be followed. By using a PTW system, companies can lower the chance of accidents, keep workers safe, and meet safety regulations.

What Is a Permit to Work?

A permit to work is a written approval that must be given before starting certain high-risk jobs. It shows that the task has been checked, the risks have been identified, and the right safety steps are in place to prevent accidents or injuries.

What a Permit to Work Includes:

A clear description of the job

Hazards that could be involved

Safety measures to control the risks

Names of the people who are allowed to do the work

How long the job will take

Sign-offs from supervisors or safety officers

Permits are especially important in high-risk areas where even a small mistake can cause serious harm. They are a key part of staying safe at work and preventing accidents before they happen.

When and Where Is a Permit to Work Required?

A permit to work system is used in industries where the risk of serious injury or harm is high. These include:

Oil and gas

Construction

Manufacturing

Chemical processing

Mining

Utilities and energy

In these workplaces, certain tasks cannot begin unless a valid permit has been approved. This system helps make sure everyone involved—from safety officers to site managers—knows about the job, the risks, and the safety steps being taken. It keeps communication clear and safety a top priority.

Common Types of Permit to Work

Different high-risk tasks call for different types of permits. Each permit addresses specific hazards and ensures proper safety measures are in place before work begins. Below are some of the most common permit types used in hazardous work environments:

Hot Work Permit

Hot work permit is required for tasks that produce heat, flames, or sparks—activities that could easily ignite a fire or cause an explosion. Jobs such as welding, metal cutting, and using blowtorches all fall under this category. To keep the worksite safe, key precautions include placing fire extinguishers nearby, using gas detectors, assigning a fire watch, and clearing flammable materials from the area.

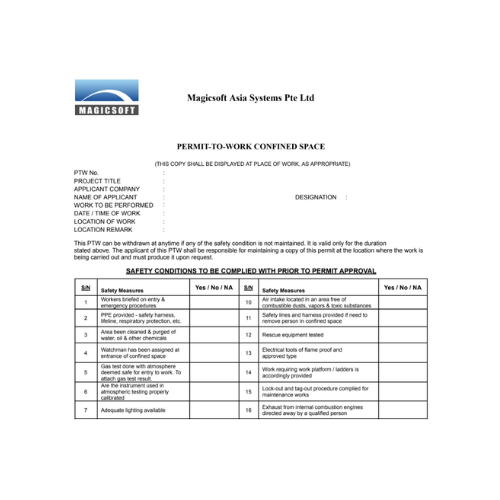

Confined Space Entry Permit

Confined Space Entry is required for tasks that produce heat, flames, or sparks, activities that could easily ignite a fire or cause an explosion. Jobs such as welding, metal cutting, and using blowtorches all fall under this category. To keep the worksite safe, key precautions include placing fire extinguishers nearby, using gas detectors, assigning a fire watch, and clearing flammable materials from the area.

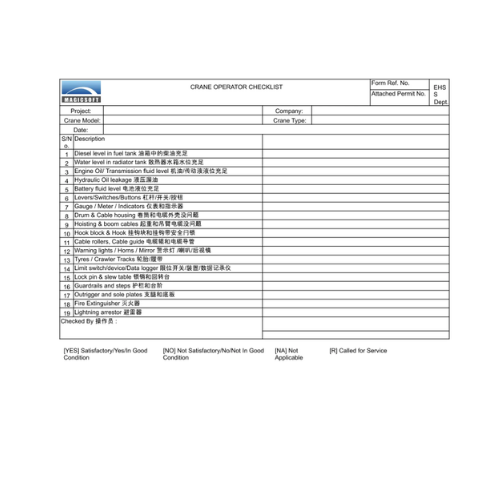

Lifting Operation Permit

When heavy loads need to be lifted using cranes, forklifts, or hoists, a lifting operation permit is necessary. These jobs carry risks such as dropped loads, equipment failure, or worker injuries. Tasks may involve moving large equipment or lifting construction materials. Safety measures include inspecting lifting equipment, securing the load properly, assigning trained signal personnel, and ensuring the lifting path is clear.

Excavation Permit

Any digging or trenching activity that might disturb underground utilities or compromise ground stability requires an excavation permit. This includes installing pipelines, laying building foundations, or trenching for cables. Before work begins, utility lines must be clearly marked, trench supports like shoring must be installed, protective barriers should be set up, and the soil’s stability must be checked.

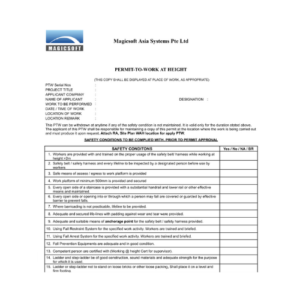

Working at Heights Permit

Working at height permit is required for any job done at an elevated location where there’s a risk of falling. Whether it’s roofing, working on scaffolding, or maintaining towers, falls from height can be fatal. To reduce the risk, workers must wear harnesses, install guardrails or safety nets, check weather conditions, and test fall arrest systems before starting.

Best Practices for Implementing a Permit to Work System

Successfully implementing a PTW system requires more than issuing forms. It demands consistency, training, and ongoing improvement.

1. Standardize Permit Formats

Use consistent templates to reduce confusion and improve understanding.

2. Train Your Workforce

Educate workers and supervisors on the importance of permits and how to use them correctly.

3. Digitize the Process

Consider using a digital system or web app to track, store, and manage permits in real time. This makes it easier to access records and reduce delays.

4. Audit Regularly

Conduct routine inspections to ensure permits are being used and followed as intended.

5. Integrate with Other Safety Systems

Link your PTW with risk assessments, toolbox talks, and incident reporting for a more holistic safety management approach.

Final Thoughts

In high-risk industries, even small mistakes can have serious consequences. That’s why a permit to work system is so important, it turns hazardous tasks into well-controlled operations, protecting both your workers and your business.

Whether you’re managing a busy construction site or handling maintenance in a confined space, a strong PTW process acts as your first line of defense against accidents and unexpected incidents.

Ready to make your safety system safer?

If you’re looking for a more efficient way to manage permits and job safety procedures, PEER can help. Designed specifically for safety officers, site supervisors, and project teams, PEER is a web-based safety platform that simplifies the permit to work process. From digital approvals to real-time monitoring, it keeps your team safe and your operations compliant.