People face hazards in every workplace, whether they work on a busy construction site or in a quiet office. When you know how to spot and control these hazards, you help create a safer workplace. Risk assessment plays a key role in keeping people safe and making sure the workplace follows safety rules.

In many countries, the law requires employers, supervisors, and self-employed individuals to carry out a risk assessment before they start any new work. This step goes beyond meeting legal requirements. It helps you build a safety culture that protects lives, prevents delays, and boosts productivity.

This article shows you how to carry out a proper risk assessment from start to finish. You will learn how to prepare for it, how to identify and evaluate risks, and how to apply the Hierarchy of Control to reduce or remove hazards.

What Is a Risk Assessment?

A risk assessment is the process of identifying hazards in the workplace, evaluating the level of risk associated with them, and implementing measures to eliminate or reduce the risks to an acceptable level. It is a proactive method of managing safety, rather than reacting to accidents after they occur.

When Should You Conduct a Risk Assessment?

You are required to review or conduct a new risk assessment:

Before starting any new work activity.

After any incident, accident, near miss, or dangerous occurrence.

When there are significant changes in work processes or environments.

When new information about potential risks becomes available.

At least once every three years as part of periodic reviews.

Preparing for a Risk Assessment

Effective risk assessments begin with solid preparation. Here’s how to get started:

1. Appoint a Risk Assessment Team

Form a multidisciplinary team with representatives from:

Safety officers

Supervisors

Workers who perform the tasks

Engineers or technical experts

2. Gather Relevant Information

Start by compiling:

A list of all work activities and processes

Equipment used

Site layout and environmental conditions

Previous incident reports and near misses

3. Break Down Work Activities

Divide each task into sub-activities for better hazard identification. For instance, “welding” can be broken down into “equipment setup,” “material handling,” and “welding operation.”

How to Conduct Risk Assessments

The risk assessment process typically follows these key steps:

Step 1 – Hazard Identification

To identify hazards, walk through the worksite and observe operations. Speak to workers, review documentation, and use your Risk Assessment Form to record observations.

Common Hazard Categories and Examples:

| Category | Examples |

|---|---|

| Physical | Fire, noise, radiation, heat |

| Mechanical | Rotating parts, moving machinery |

| Electrical | High voltage, static discharge |

| Chemical | Flammable liquids, corrosive substances |

| Biological | Viruses, bacteria, mold |

| Psychosocial | Stress, fatigue, isolation |

Proximity of hazards: For example, workers near noisy machines may also be affected.

Incompatible tasks: Hot work near spray painting areas increases fire risk.

Non-routine operations: Maintenance and shutdowns often introduce overlooked hazards.

Environmental conditions: Outdoor work during haze periods raises respiratory risks.

Vulnerable employees: Pregnant workers, older adults, or those with health conditions may need extra protection.

Step 2 – Risk Evaluation

After identifying hazards, assess the likelihood and severity of each. Use a risk matrix to categorize the risk as low, medium, or high.

Evaluation Criteria:

- Likelihood: How probable is the hazard to cause harm?

- Severity: What is the extent of potential harm?

For Health Hazards:

Conduct hygiene monitoring (e.g., air sampling for toxic fumes or noise level checks) to determine workers’ exposure and compare with permissible limits.

Step 3 – Risk Control

After you’ve evaluated the risks of each hazard, you should take appropriate action to eliminate or minimise those risks. Reasonably practicable measures should be taken to protect people from harm.

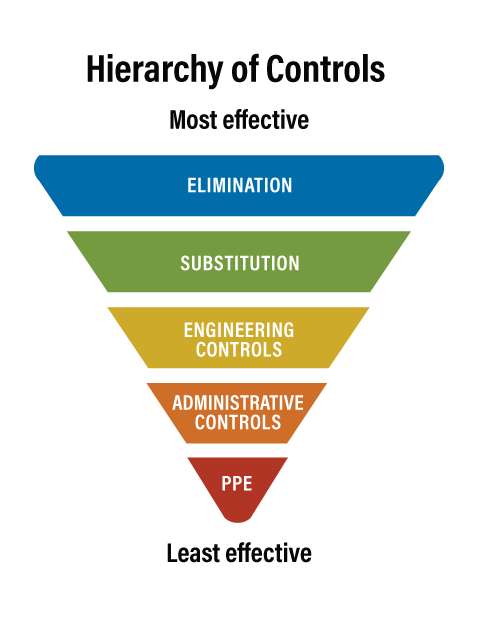

You should select your risk control measures based on the Hierarchy of Control. Upstream risk controls (e.g. elimination, substitution and engineering controls) are more effective in reducing or controlling risk, and should be considered first.

You should consider using a combination of control measures from the Hierarchy of Control as no single measure is usually sufficient to control the risk. For example, engineering controls need to be implemented together with administrative controls such as training and safe work procedures to address the hazard sufficiently.

Personal protective equipment (PPE) should be explored only after upstream risk controls have been considered, as a short-term contingency during emergency, maintenance, repair or as an additional protective measure against residual risks. The effectiveness of PPE depends greatly on whether it is chosen and fitted correctly, worn at all times and maintained properly.

For hazards that cannot be controlled immediately, interim control measures should be implemented while establishing longer term measures to reduce the risk level. Work should not start if the risk remains high.

Digitize Your Workplace Safety

Simplify your WSH processes to stay compliant and audit-ready.Digitize Risk Assesment

Manual risk assessments work well, but digitizing the process increases accuracy and efficiency. Web-based safety apps like PEER streamline the risk assessment process for safety officers, site managers, and business owners.

PEER lets you:

- Build custom checklists

- Record hazards and risk levels

- Assign corrective actions

- Automatically schedule review dates

- Access your risk register anytime, anywhere

This modern, web-based platform simplifies use in fast-changing environments where risk factors frequently shift. By centralizing your safety data, it makes compliance easier and boosts accountability, which improves safety and simplifies your job.

Final Thoughts

Risk assessments are not just compliance documents but vital tools for creating a safer, healthier workplace. By identifying hazards early and applying the right controls, you protect not only your workers but also your company’s operations and reputation.